How To Hide Plywood Under Quartz Countertops

Dwelling styles change through the years. While there are classic styles which stay with the states forever and in that location are people who are specifically trying to capture the manner of a particular era, that's not the majority of people. Most people would rather become for something modern, following the trends of style to take their home built or remodeled to any the current style is.

In kitchens, much of the styling trend has been in countertop materials used. While there are ever less common materials that are used, there have been trends through the years, with different materials becoming the well-nigh popular for a time.

Formica laminate became the almost popular countertop fabric after the end of World War Ii and retained that coveted position for half a century. It wasn't until Corian countertops came along, that Formica lost its spot as the number one countertop roofing. But the superior durability of Corian, along with the ability to sand it down and refinish it, allowed Corian to accept over from Formica in the 1990s.

At nigh the same time that corian became popular, granite came along, competing with it, along with marble and other more exotic materials. But the big advantage Corian had was cost. Over time the trend has been more to granite, with it becoming so popular that the major dwelling improvement centers all offering it equally an option.

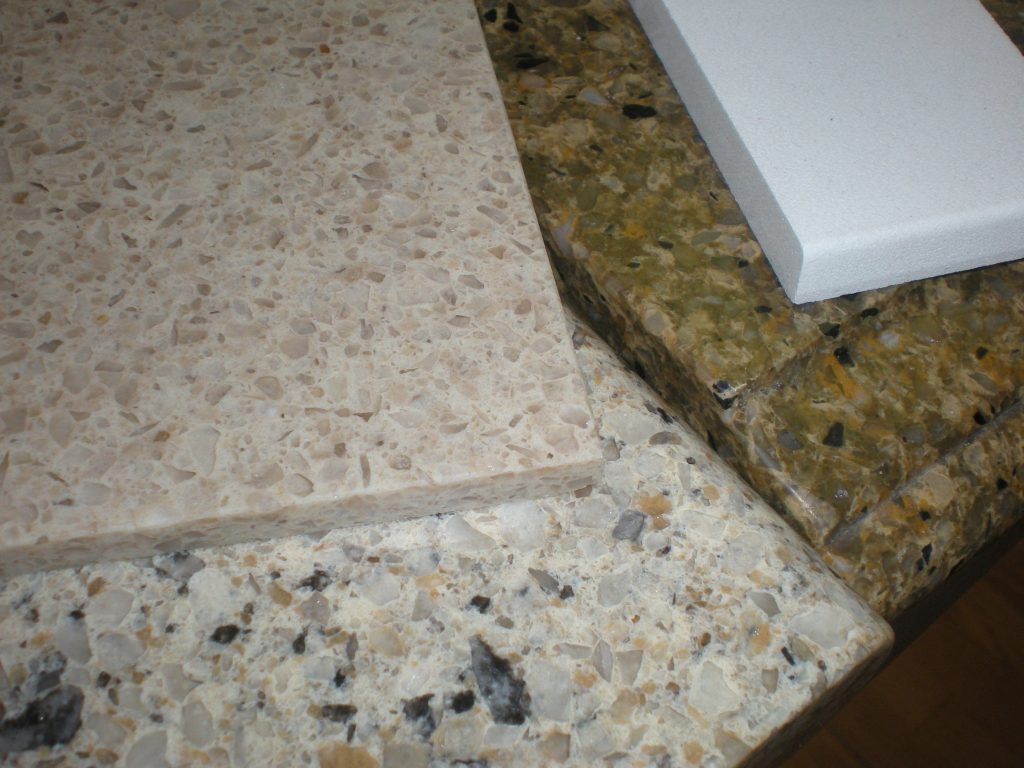

In more than recent years, some other competitor has taken the place as the trend-setter, quartz. Since near 2004, quartz has been climbing and is now considered the mode to go. Slightly more expensive than granite, quarts is more than on the lodge of the toll of marble, making it ane of the more costly options available. Today's quartz countertops are actually engineered quartz, allowing for a much broader diverseness in appearance. Today's engineered quartz countertops can take on the appearance of almost any mineral desired.

Quartz is a mineral, making it extremely hard and non-porous. That means that information technology doesn't scratch and won't stain. Unlike granite, the surface doesn't take to be sealed.

Some people mistake engineered quartz countertops for corian, thinking they are both the same, as both use a combination of minerals and polymers. Nonetheless, Corian uses roughly 66% mineral content, with the rest beingness Acrylic plastic. Quartz, on the other hand, is over ninety% mineral, with less than ten% rosins and polymers. In adjacent comparisons, quartz looks more than like real stone, while Corian tends to have an bogus await. But then, Corian never intended to look like a real stone.

Quartz is ordinarily idea of as being heat-resistant, able to withstand temperatures upwardly to 400°F. Even so, even though this is truthful, there is something called "thermal shock." The rapid change of temperature caused by setting a hot pan or bag of ice on the counter could put enough strain on the material that it will cause cracking.

Quartz Countertop Thicknesses

Not all quartz countertops are equal; a lot depends on the thickness of the textile. Manufacturers supply it in 1cm, 2 cm and 3 cm thicknesses, with some replacing the 1 cm thickness with a 1.two cm version. The various thicknesses are an attempt to achieve potential customers at unlike price points.

The thinner quartz is basically just found in prefabricated countertops. Most of these come from overseas factories and have a laminated edge which has already been smoothed, making the countertop gear up for installation. The "laminated edge" is made by cutting a sparse strip of the same cloth that the countertop is fabricated of and gluing it to the bottom of the main body of the countertop, then finish off the border smoothly. This is also done at times with 2 cm countertops, giving them a 4 cm thick edge.

These thinner countertops always require a layer of plywood underneath them for support. The maximum distance the countertop material itself tin can span, without support, is 12".

In that location is a grade of quartz that is referred to equally vertical quartz, which is substantially identical to the 1 cm countertop material. This thickness is fine for vertical applications, as information technology is always installed up against plywood or drywall, which will support it.

Meliorate quality prefab countertops use two cm quartz, either with or without a laminated border. The added thickness means that the countertop can span up to 24" without support. A plywood backer is not required, unless the countertop is going to span areas wider than that. But since nearly base cabinets are wider than 24", information technology is unremarkably a good idea to put a layer of plywood under the countertop. In this case, a laminated edge is used, to hide the plywood.

Dwelling builders looking to provide an upscale appearance, while still controlling price will often utilise two cm quartz to salvage coin. This gives a high cease look, while saving on the overall material costs. Since virtually people don't know the difference they are able to go away with it.

However, the best quartz countertops are 3 cm thick. The added thickness provides a more than massive appearance, without having to resort to a laminated edge. Due to the force of the thicker material, plywood backing is not unremarkably needed.

Installing Quartz Countertops

The biggest thing to consider when installing quartz countertops is the span between supports. As mentioned in the last section, the norm is to add together plywood back up for spans over 24".

But what about installing countertops with overhangs? Adding an eating area to a countertop or creating a wide countertop to provide extra work area, particularly on islands, has become quite popular. But the material used has to be able to back up it.

By and large, overhangs cannot extend more than i/3 the total countertop depth, without support, up to a maximum extension of fifteen". Should a greater overhang be desired, the addition of corbels will exist required. These need to be designed to exist appropriate to support the weight of the countertop and exist attached to something which will provide the necessary structural support, such every bit a 2×4. The maximum spacing betwixt corbels is 36". With corbels, the countertop can take an overhang of up to 24", but the overhang past the cease of the corbels must yet be less than one/3 the total counter depth, with a maximum of xv". Beyond 24", the addition of posts is required, forth with a full plywood substrate. These posts cannot exist more than than 36" apart.

Before the new quartz countertops are installed, the existing countertops and sink and stove height (if installed) need to be removed. This too means disconnecting the sink plumbing; both the feed lines and the drain line. The countertop is usually installed witH clips, property it to the base cabinets.

The new countertop will demand to be cut past a stone countertop supplier. This is typically done off of a template, rather than just dimensions. If dimensions are provided, they unremarkably don't take into account whatever curved areas in the wall or angles which aren't true. By making a template out of strips of Luan plywood, glued together with hot melt glue, the exact size needed can be adamant, allowing the fabricator to make the countertop fit exactly.

Actual cut of the countertop, including cutting out for the sink and making hole for the faucet is done with a wet saw, making it impossible for most people to practise themselves.

Before installing the countertop, the peak edge of the cabinets needs to exist checked to ensure that it is level and smooth. Whatever high or low points in the edge should exist leveled out, either by cutting them downwardly or shimming. If a plywood support is required, it should be installed before the countertop arrives.

The countertop itself is actually installed with adhesive, either an acrylic adhesive or silicone caulking. The shop which prepared the countertop may have also glued some metallic clips on the bottom of the countertop, assuasive screws to be inserted, attaching the countertop in place, while the adhesive cures. If a matching quartz backsplash is installed, it will too be installed with silicone caulking every bit the adhesive.

These countertops apply an undermount sink, rather than i with a flange that overlaps the countertop on the elevation side. The undermount sink provides a cleaner overall appearance, while eliminating 1 of the biggest bacteria traps in the kitchen. The undermount sink is installed with a combination of silicone caulking and clips, just as the countertop is.

The countertop and sink needs to be left 24 hours for the adhesives to cure, before using.

Source: https://theplywood.com/quartz-countertops/

0 Response to "How To Hide Plywood Under Quartz Countertops"

Post a Comment