What Size Drill Bit To Use

Drill $.25 are the cutting tools of drilling machines. They can be made in whatsoever size to social club, but standards organizations have defined sets of sizes that are produced routinely by drill bit manufacturers and stocked by distributors.

In the U.S., fractional inch and judge drill bit sizes are in common employ. In about all other countries, metric drill bit sizes are most common, and all others are anachronisms or are reserved for dealing with designs from the US. The British Standards on replacing estimate size drill bits with metric sizes in the UK was first published in 1959.[ citation needed ]

A comprehensive table for metric, fractional wire and tapping sizes can be found at the drill and tap size nautical chart.

Metric drill fleck sizes [edit]

Metric drill gear up, ane.0–6.0 mm by 0.1 mm, jobber length. The case that holds them in an indexed order (by size), via a graduated serial of holes, is called a drill index.

Metric drill chip sizes define the bore of the chip in terms of standard metric lengths. Standards organizations define sets of sizes that are conventionally manufactured and stocked. For instance, British Standard BS 328 defines 230 sizes from 0.two mm to 25.0 mm.

From 0.two through 0.98 mm, sizes are defined as follows, where North is an integer from two through nine:

- N · 0.1 mm

- N · 0.i + 0.02 mm

- Due north · 0.1 + 0.05 mm

- N · 0.1 + 0.08 mm

From 1.0 through two.95 mm, sizes are defined as follows, where Due north is an integer from x through 29:

- Due north · 0.1 mm

- North · 0.ane + 0.05 mm

From 3.0 through thirteen.9 mm, sizes are defined as follows, where N is an integer from xxx through 139:

- Northward · 0.i mm

From 14.0 through 25.0 mm, sizes are defined equally follows, where M is an integer from 14 through 25:

- One thousand · one mm

- M · 1 + 0.25 mm

- Thousand · 1 + 0.5 mm

- Grand · 1 + 0.75 mm

In smaller sizes, bits are available in smaller diameter increments. This reflects both the smaller drilled pigsty diameter tolerance possible on smaller holes and the wishes of designers to accept drill bit sizes available within at well-nigh 10% of an arbitrary hole size.

The price and availability of particular size bits does not alter uniformly beyond the size range. Bits at size increments of i mm are nigh commonly available, and lowest cost. Sets of bits in 1 mm increments might be found on a market stall. In 0.five mm increments, any hardware shop. In 0.1 mm increments, any engineers' store. Sets are non ordinarily bachelor in smaller size increments, except for drill bits below ane mm diameter. Drill bits of the less routinely used sizes, such as 2.55 mm, would accept to exist ordered from a specialist drill flake supplier. This subsetting of standard sizes is in contrast to general practice with number guess drill $.25, where information technology is rare to find a set on the market which does not incorporate every approximate.

In that location are too Renard series sequences of preferred metric drill bits:[1]

- R5 (factor one.58) : M2.v, M4, M6, M10, M16, M24

- R10 (factor 1.26): M3, M5, M8, M12, M20, M30

Metric dimensioning is routinely used for drill bits of all types, although the details of BS 328 apply only to twist drill bits. For example, a set up of Forstner bits may contain ten, 15, xx, 25 and 30 mm diameter cutters.

Partial-inch drill bit sizes [edit]

Fractional-inch drill bit sizes are however in common use in the United States and in whatever factory (around the earth) that makes inch-sized products for the U.S. market.

ANSI B94.11M-1979 sets size standards for jobber-length directly-shank twist drill bits from 1/64 inch through ane inch in i/64 inch increments. For Morse taper-shank drill bits, the standard continues in ane/64 inch increments up to 1¾ inch, then 1/32 inch increments up to 2¼ inch, 1/16 inch increments up to 3 inches, 1/8 inch increments up to iii¼ inches, and a unmarried 1/4 inch increase to three½ inches. I aspect of this method of sizing is that the size increment between drill $.25 becomes larger as bit sizes get smaller: 100% for the footstep from 1/64 to 1/32, but a much smaller percentage between 1 47/64 and 1 iii/iv.

Drill bit sizes are written equally irreducible fractions. So, instead of 78/64 inch, or 1 14/64 inch, the size is noted every bit 1 vii/32 inch.

Below is a chart providing the decimal-fraction equivalents that are most relevant to partial-inch drill bit sizes (that is, 0 to 1 by 64ths). (Decimal places for .25, .5, and .75 are shown to thousandths [.250, .500, .750], which is how machinists usually think about them ["two-fifty", "five hundred", "seven-fifty"]. Machinists generally truncate the decimals subsequently thousandths; for example, a 27/64" drill scrap may be referred to in shop-floor speech equally a "four-20-i drill".)

Charts like this, printed at poster size, are widely posted on motorcar shop walls for handy reference by machinists equally they work. For some tasks it is faster and less abrasive to glance down a column of numbers on a poster than information technology is to punch calculator buttons or practise penciled arithmetics.

For anyone looking to create such a affiche or to tailor the design and colors to their own preferences, spreadsheet software makes this fast and easy to do. The tools that the software provides—formulas, cell formatting with rounding, autofill, and sorting past numerical society—obviate any manual calculation and data entry. For example, ane can create the inch nominal rows for the chart—with columns for inch fraction, inch decimal, and respective millimeter decimal conversion—using formulas, cell formatting with rounding, and autofill; and one can then create the metric nominal rows below that, with the inch decimal conversions existence provided by formula; and then one can sort the whole canvass by size lodge, automatically interposing the inch nominal and metric nominal rows past size gild. Font and colour can be chosen to make a poster-size chart that is easy to read from i or 2 meters away. Press can exist washed on a desktop printer, with the letter-size sheets then being stapled together to make upward the larger affiche.

Decimal-fraction equivalents [edit]

|

|

|

|

Number and letter gauge drill bit sizes [edit]

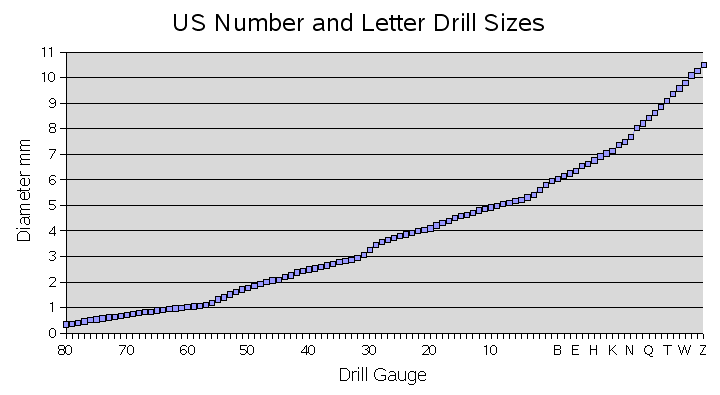

Number drill flake gauge sizes range from size fourscore (the smallest) to size 1 (the largest) followed by letter estimate size A (the smallest) to size Z (the largest). Although the ASME B94.11M twist drill standard, for example, lists sizes every bit pocket-sized every bit size 97, sizes smaller than 80 are rarely encountered in exercise.

Number and letter sizes are commonly used for twist drill $.25 rather than other drill forms, every bit the range encompasses the sizes for which twist drill $.25 are most ofttimes used.

The gauge-to-diameter ratio is not defined by a formula; it is based on—but is not identical to—the Stubs Steel Wire Estimate, which originated in United kingdom during the 19th century.[two] The accompanying graph illustrates the change in diameter with modify in gauge, every bit well equally the reduction in footstep size equally the approximate size decreases. Each pace along the horizontal axis is one gauge size.

Number and letter gauge drill $.25 are all the same in common employ in the U.S. and to a lesser extent the U.k., where they take largely been supplanted by metric sizes. Other countries that formerly used the number serial have for the most part also abased these in favour of metric sizes.[ citation needed ]

Drill bit conversion table [edit]

![]()

click to encounter a ruler comparing millimeters to fractions of an inch

|

|

|

|

|

Screw-machine-length drill [edit]

The shortest standard-length drills (that is, lowest length-to-diameter ratio) are screw-machine-length drills (sometimes abbreviated South/M). They are named for their apply in screw machines. Their shorter flute length and shorter overall length compared to a standard jobber scrap results in a more rigid drill bit, reducing deflection and breakage. They are rarely bachelor in retail hardware stores or dwelling house centers.

Jobber-length drill [edit]

Jobber-length drills are the most commonly found type of drill. The length of the flutes is between 9 and 14 times the diameter of the drill, depending on the drill size. Then a 1 / 2 in (12.7 mm) diameter drill volition exist able to drill a hole 4+ ane / two in (114.3 mm) deep, since it is 9 times the diameter in length. A ane / eight in (3.175 mm) diameter drill tin drill a hole 1+ five / 8 in (41.275 mm) deep, since it is thirteen times the diameter in flute length.[3]

The term jobber refers to a wholesale distributor—a person or visitor that buys from manufacturers and sells to retailers.[ citation needed ] Manufacturers producing drill bits "for the trade" (as opposed to for specialized machining applications with item length and design requirements) made ones of medium length suitable for a wide variety of jobs, because that was the type almost desirable for full general distribution. Thus, at the fourth dimension that the name of jobber-length drill $.25 became mutual, information technology reflected the same concept that names like general-purpose and multipurpose reverberate.[ citation needed ]

Aircraft-length drill [edit]

Extended-reach or long-series drills are commonly chosen aircraft-length from their original use in manufacturing riveted aluminum shipping. For bits thicker than a minimum size such as 1⁄8 -inch (3.175 mm), they are available in fixed lengths such as vi, 8, 12 or 18 inches (152, 203, 305 or 457 mm) rather than the progressive lengths of jobber drills.

11/32 inch drills: long-series Morse, plain Morse, jobber

The epitome shows a long-series drill compared to its diametric equivalents, all are eleven⁄32 inch (8.7313 mm) in diameter. The equivalent Morse taper drill shown in the centre is of the usual length for a taper-shank drill. The lower drill fleck is the jobber or parallel shank equivalent.

Eye drill bit sizes [edit]

Middle drills, numbers 1 (bottom) through to 6 (top)

Center drills are available with two different included angles; 60 degrees is the standard for drilling centre holes (for instance for subsequent eye support in the lathe), but 90 degrees is also common and used when locating holes prior to drilling with twist drills. Center drills are made specifically for drilling lathe centers, just are oftentimes used every bit spotting drills because of their radial stiffness.

|

|

Spotting drill bit sizes [edit]

Spotting drills are available in a relatively small-scale range of sizes, both metric and imperial, as their purpose is to provide a precise spot for guiding a standard twist drill. Commonly bachelor sizes are 1/viii", 1/iv", 3/eight", ane/two", 5/8", 3/four", iv mm, 6 mm, eight mm, 10 mm, 12 mm, 14 mm, 16 mm and 18 mm. The drills are well-nigh unremarkably available with either 90° or 120° included angle points.

See likewise [edit]

- Drill and tap size chart

References [edit]

- ^ Dasarathi-Cadem (2 February 2017). "Preferred sizes in technology". CNC etc . Retrieved 6 September 2017.

- ^ Pöll, J. South. (June 1999). "The story of the guess". Anaesthesia. 54 (6): 575–581. doi:10.1046/j.1365-2044.1999.00895.x. ISSN 0003-2409. PMID 10403873. S2CID 41519791.

- ^ "Jobber Length Twist Drill Sizes".

What Size Drill Bit To Use,

Source: https://en.wikipedia.org/wiki/Drill_bit_sizes

Posted by: lightliess1983.blogspot.com

0 Response to "What Size Drill Bit To Use"

Post a Comment